November 14, 2025

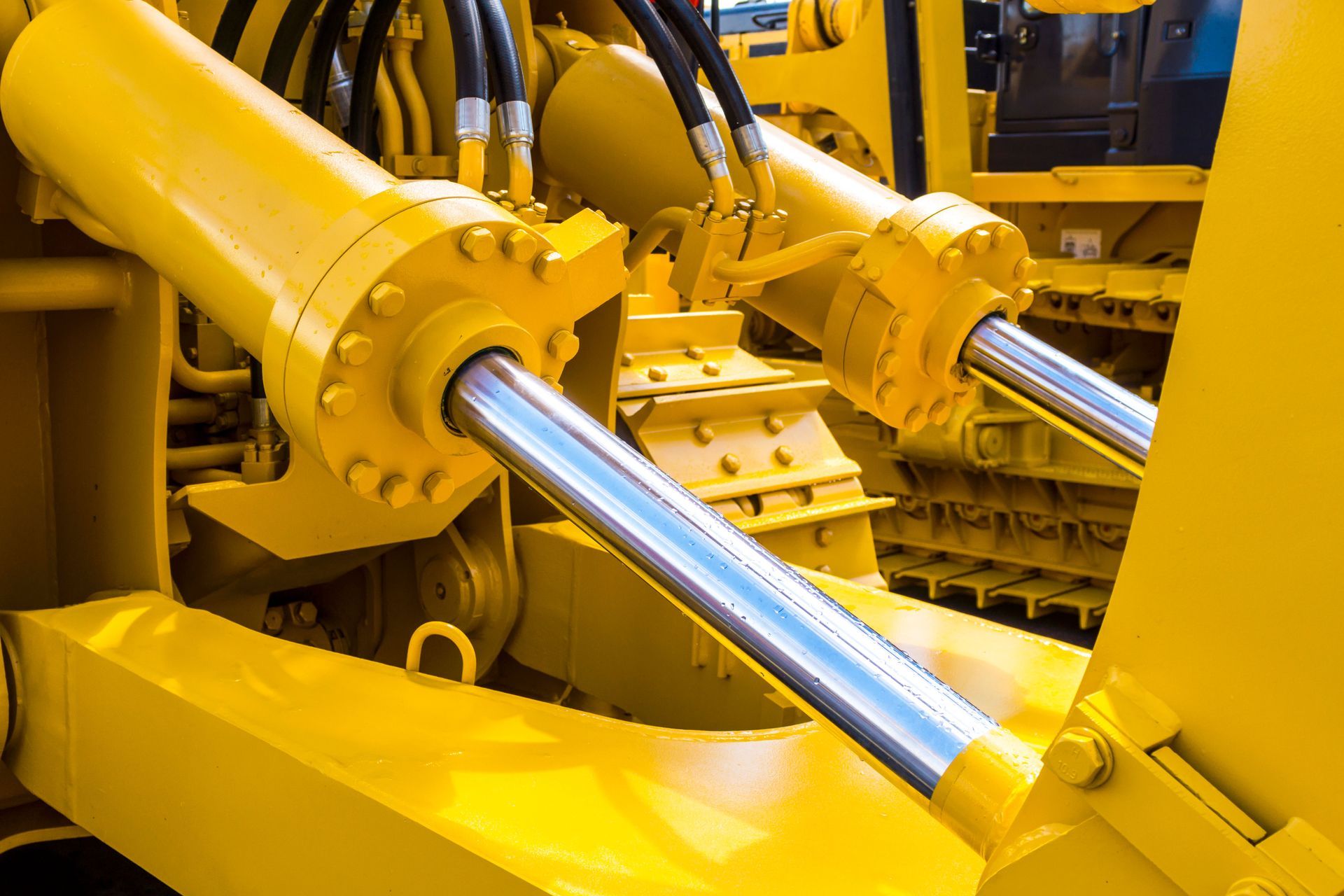

In this article, we'll explore the essential components and processes involved in professional hydraulic cylinder repairs. As crucial components of many machines, hydraulic cylinders play an indispensable role in industrial and heavy machinery operations. Understanding the repair process can lead to better maintenance practices and extended life for these critical components. By delving into what a professional hydraulic cylinder repair entails, we'll shed light on the intricacies involved and offer guidance on maintaining these complex systems.

Prioritize Safety Before Beginning Repairs

Safety is paramount when it comes to hydraulic cylinder repairs. Before any work begins, professionals ensure that the equipment is fully powered down and the hydraulic system is depressurized. This precaution is vital to prevent accidents resulting from residual pressure in the system. It is also critical to make sure that all personnel working on the cylinder are aware of the potential hazards and are trained in appropriate safety practices. Proper personal protective equipment (PPE), such as gloves and eye protection, must be used to prevent injury from sharp tools and small particles.

In addition to wearing the right protective gear, workplaces should have clearly defined emergency procedures and accessible first-aid kits. Proper ventilation is important to avoid inhaling any potentially harmful fumes from hydraulic fluid. A safety checklist is often employed to ensure that every step is taken into account before proceeding with disassembly. The physical environment should be adequately lit, free from obstacles, and organized to prevent tripping hazards or tool mishaps. Taking time in the initial stages to set up a safe working environment can significantly reduce the risk of injury.

Remove the Hydraulic Cylinder With Care

Once safety precautions are assured, the next step is removing the hydraulic cylinder from the equipment. This task calls for careful handling to avoid damaging the cylinder or other machine components. Proper documentation and labeling of hydraulic lines and connections are crucial for an error-free reassembly. Technicians often use specialized tools like spanner wrenches and lifting devices to detach the cylinder from the equipment. The use of these tools ensures controlled movement and minimizes the risk of dropping or mishandling the cylinder.

The removal process involves disconnecting the hydraulic and mechanical connections. Hydraulic lines are capped or plugged to prevent fluid loss and contamination. Care is taken to avoid introducing dirt or debris into the hydraulic lines, as this could lead to future issues. In some cases, the equipment might need to be placed on supports or jacks to ensure stability during the removal process. Technicians meticulously follow the manufacturer’s guidelines to ensure a smooth removal operation.

Disassemble Components for Accurate Diagnosis

Once the cylinder is removed, it must be disassembled to diagnose issues accurately. The cylinder is secured on a workbench that provides stability, allowing precise handling of its components. Disassembly involves removing the end caps, piston rod, seals, and other internal parts. Each component is carefully extracted and inspected for wear and damage. Paying close attention to the order of disassembly simplifies the reassembly process later on.

Proper disassembly techniques prevent further damage to sensitive components. Specialized tools, including seal picks and pin spanner wrenches, are often needed to access and release cylinder parts. Misuse of tools can result in scratches or gouges that compromise cylinder functionality. As each component is removed, technicians examine its condition and take notes on areas requiring attention. This early identification goes a long way in easing hydraulic cylinder repairs and reassembly stages.

Inspect and Identify Damaged or Worn Parts

Identifying worn or damaged parts is a crucial part of hydraulic cylinder repairs. Every component is inspected for signs of wear, such as scoring, corrosion, or cracks. These defects can compromise the performance and safety of the hydraulic system. Parts such as seals, rods, and pistons are typically subject to scrutiny, given their role in maintaining the cylinder's integrity. Early detection of faults allows for timely intervention and replacement of compromised parts.

Throughout the inspection, technicians use precise measuring tools to assess the condition of the components. Dial indicators and calipers provide metrics against manufacturer standards, ensuring parts meet predefined tolerances. Understanding the degree of wear is vital to making decisions about whether to repair or replace components. According to Business Research Insights, hydraulic cylinders account for nearly 58% of the total hydraulic component repair market, underscoring the importance of accurate diagnostics and preventive maintenance in extending their service life. Replacement of severely damaged parts is essential to restore the cylinder's original functionality. Proactive assessment enables technicians to identify potential failure points and mitigate risks.

Clean and Reassess All Cylinder Components

Thorough cleaning of all components is obligatory to remove grime and particles not visible to the naked eye. Components are subjected to cleaning protocols that include degreasers, solvents, and lint-free wipes. Removing contaminants is crucial for proper inspection and subsequent reassembly, as they can impede function if left unchecked. Technicians also utilize compressed air to clear tight areas and passages. By ensuring pristine cleanliness, technicians reduce the risk of damage caused by contaminants.

After cleaning, each part undergoes meticulous re-examination for defects or hidden damage. Reference diagrams and service manuals aid in confirming the physical and operational integrity of components. Optical aids like magnifying glasses further assist in revealing any hidden issues. A safe and thorough inspection process helps in determining the viability of reusing or replacing components for optimal hydraulic cylinder repairs. The goal is to pinpoint potential issues that might affect the future operational stability of the cylinder.

Prepare and Organize Parts for Reassembly

Prepared components form the foundation of successful hydraulic cylinder repairs. Pre-assembly involves gathering all required replacement parts and organizing cleaned components. Technicians catalog components according to a predefined sequence for smooth and error-free reassembly. Proper lubrication of parts before assembly further ensures their correct function and long-term durability. Lubricants are specially chosen to extend part life and enhance operational performance.

Reinstall the Piston and Rod With Precision

Reinstalling the piston and rod in a hydraulic cylinder is a deliberate process that requires accuracy. The first step is ensuring that the piston is properly aligned with its corresponding rod. Misalignment can lead to operational inefficiencies and potential damage. This phase requires the utilization of specific tools to maintain alignment and prevent scoring or scratching the cylinder bore. Attention to tightness and torque specifications is crucial for preventing leaks and ensuring performance.

Install Seals and Gaskets to Prevent Leaks

Seals and gaskets are integral components in ensuring hydraulic cylinder integrity. They prevent fluid leaks and maintain pressure within the system, crucial elements in effective cylinder repair. Incorrect installation of seals and gaskets can lead to system inefficiencies or, worse, total failure. These components need to be properly chosen for their application and installed with precision to avoid compromise. The careful installation of sealing components is indispensable to achieving long-term reliability and functionality.

Secure Hydraulic Connections for Optimal Performance

Proper hydraulic connections are a vital component for hydraulic cylinder repairs. Incorrect or loose connections risk system failure and fluid loss, posing hazards to personnel and equipment. Ensuring tight and secure hydraulic connections promotes system stability. This reassembly phase demands a thorough check of hoses, fittings, and threaded connections to confirm their tightness and alignment. Using torque wrenches, technicians ensure connection integrity for seamless operation.

Professional hydraulic cylinder repair involves a meticulous process of inspection, diagnosis, and reassembly. Understanding these steps can help equipment operators maintain their machinery effectively and avoid prolonged downtime. The journey from identifying issues to successfully testing a cylinder's functionality is comprehensive, ensuring the reliability and longevity of machinery. Professionals performing hydraulic cylinder repairs adhere to high standards of safety, precision, and quality. By emphasizing proper repair practices, businesses can achieve efficient hydraulic system operation while minimizing future maintenance needs. Reach out to Rivas Hydraulics LLC to learn more about our services today!