January 15, 2026

In the fast-paced world of industrial and construction operations, equipment downtime can be more than an inconvenience—it can be extremely costly. Machinery that isn’t running efficiently slows productivity, increases repair costs, and creates stress for operators. That’s why skilled hydraulic repair services are critical. By combining expertise, advanced tools, and preventive strategies, these services can extend the life of hydraulic systems, improve performance, and protect your operational investments. Whether you operate heavy machinery on construction sites or precision equipment in factories, investing in professional hydraulic repair services is a step toward operational stability and long-term savings.

The Critical Role of Hydraulic Systems in Machinery

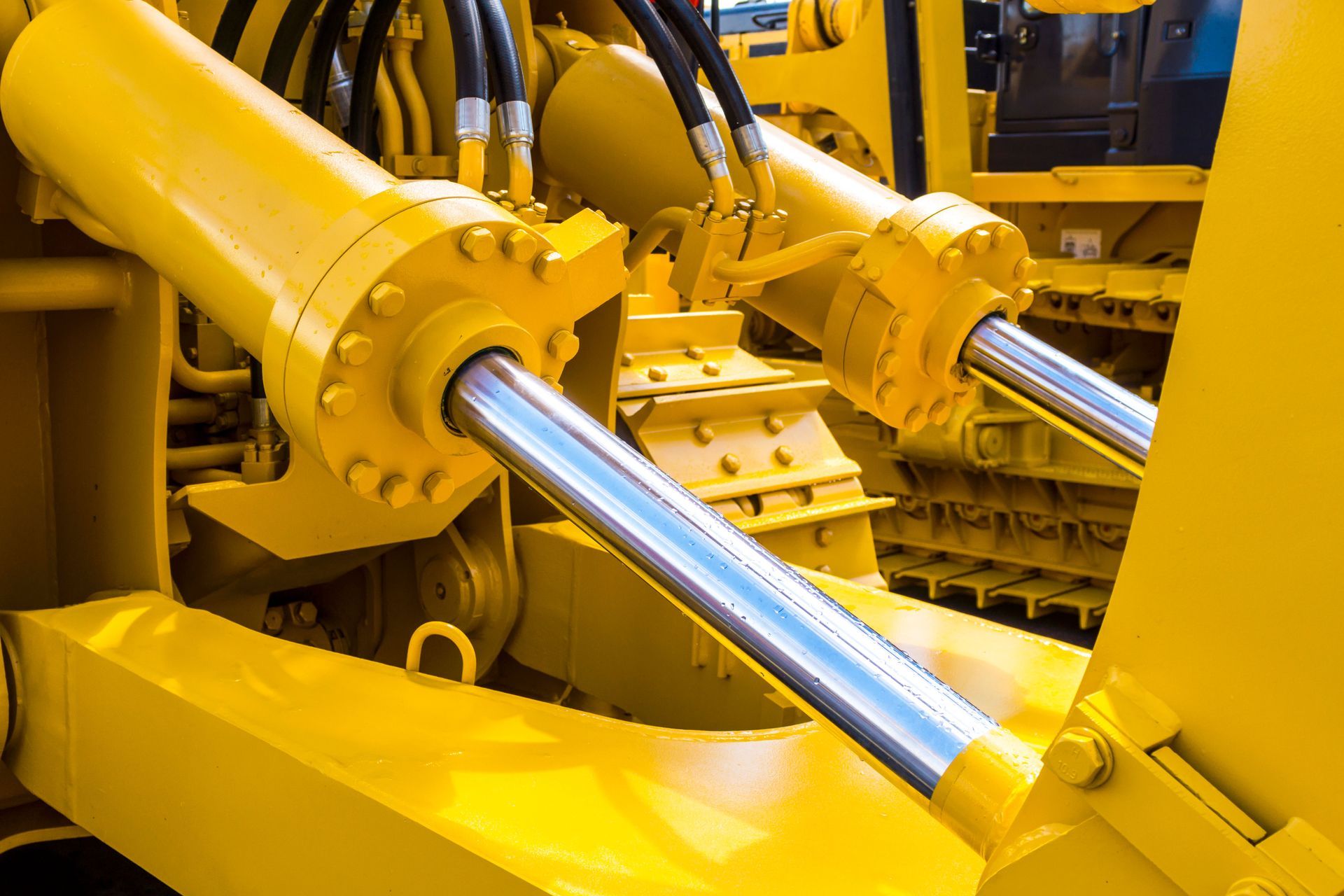

Hydraulic systems are the unsung heroes of modern machinery. They transfer energy through pressurized fluids to power movement, lift heavy loads, and execute precise tasks. From construction equipment and forklifts to manufacturing machinery, hydraulics enable machines to operate at maximum efficiency.

Hydraulics also allow for a level of precision and control that other systems cannot match. For example, in construction, a hydraulic excavator can maneuver large loads with millimeter accuracy, preventing material damage and improving overall safety on-site. Proper maintenance through skilled hydraulic repair services ensures that these systems continue to deliver reliable and consistent performance. When hydraulic systems are in good condition, machinery runs smoother, energy use is optimized, and workplace safety is enhanced.

Common Obstacles That Threaten System Performance

Hydraulic systems are reliable, but they’re not immune to challenges. Contaminated fluid—caused by dust, moisture, or air infiltration—can erode components, trigger corrosion, and reduce efficiency. Leaks from worn hoses, seals, or fittings lower system pressure, waste fluid, and may pose environmental hazards. Excessive heat is another common issue, as high temperatures degrade fluid and place stress on critical parts. It’s also worth noting that hydraulic cylinders account for approximately 58% of the total hydraulic component repair market, according to Business Research Insights. These components are particularly prone to wear, making them a frequent focus for skilled repair services. Cylinders can develop internal scoring or seal failures, which if left unchecked, reduce lift capacity and precision.

Another obstacle is improper system calibration. Over time, pressures and flow rates may drift from manufacturer specifications due to component wear. Even minor deviations can reduce operational efficiency, increase energy consumption, and accelerate part deterioration. Skilled hydraulic repair services address these issues by recalibrating systems and replacing worn parts before they compromise overall functionality. By doing so, businesses can maintain productivity and prevent unexpected system failures.

Financial Consequences of Equipment Downtime

When hydraulic equipment fails, the consequences extend far beyond repair bills. Production lines can grind to a halt, project timelines may slip, and companies can face penalties or lost revenue. Emergency repairs often require expedited shipping for replacement parts and additional labor hours, driving up costs. Downtime can also affect relationships with clients or partners. A construction company with idle machinery may miss project milestones, leading to delays for other contractors. Manufacturing plants can experience bottlenecks in supply chains, disrupting delivery schedules and customer satisfaction.

Regular hydraulic repair services help mitigate these risks by catching problems early and performing preventive maintenance. Operators gain confidence knowing their machines are reliable, and businesses maintain smooth operations. Ultimately, avoiding unplanned downtime not only saves money but also preserves the company’s reputation and operational stability. Investing in skilled hydraulic repair services is a strategic choice for any business reliant on heavy or precision machinery.

Preventive Strategies for Long-Lasting Hydraulics

Preventive maintenance is key to extending the lifespan of hydraulic systems. This approach involves scheduled inspections, fluid analysis, and timely replacement of worn components. By detecting small issues before they escalate, businesses can avoid major breakdowns that disrupt production.

Fluid monitoring is especially important. Analyzing hydraulic oil for contamination or degradation helps technicians intervene before parts are damaged. For example, detecting water contamination early can prevent rusting of internal surfaces, while identifying metal particles in the fluid may reveal component wear before a catastrophic failure occurs. Using high-quality fluids and maintaining proper system pressures reduces wear, prevents overheating, and keeps machines running efficiently.

In addition, preventive strategies include regular filter changes, alignment checks, and system flushing when needed. Skilled hydraulic repair services often implement scheduled maintenance plans tailored to the operating environment. For instance, machinery operating in dusty outdoor conditions may require more frequent fluid analysis and filter replacement than indoor systems. By customizing preventive measures, businesses protect their equipment and ensure consistent, long-term performance.

Expertise Behind Skilled Hydraulic Repair Services

Professional hydraulic repair services combine certified technicians with advanced technology to deliver precise, lasting solutions. Technicians use diagnostic tools to measure system pressures, flow rates, and temperature variations, quickly identifying anomalies. State-of-the-art equipment like thermal imaging cameras, particle counters, and ultrasonic leak detectors allows repairs to be targeted and effective.

Experienced technicians bring practical knowledge gained from working with a variety of machines across industries. They can anticipate potential issues, customize repair strategies, and ensure repairs align with manufacturer specifications. This expertise not only resolves current problems but also reduces the likelihood of future failures. Technicians also educate operators about best practices, such as proper system warm-up procedures and fluid handling, creating a proactive culture around equipment care.

Advanced technologies also allow repair services to document system health over time. By tracking trends in fluid condition, pressure performance, and component wear, technicians can predict future maintenance needs, helping businesses plan budgets and avoid unexpected costs. In this way, skilled hydraulic repair services combine hands-on expertise with technological insights to maximize equipment reliability.

Timely Interventions for Optimal Equipment Life

Addressing wear and tear promptly is essential for hydraulic longevity. Components like hoses, valves, seals, and cylinders can deteriorate over time, and small problems can quickly escalate into major failures. Timely repairs prevent cascading damage, minimize downtime, and maintain energy efficiency.

Regular servicing ensures that equipment operates consistently at peak performance. Flow inconsistencies are corrected, pressure stability is maintained, and overall system efficiency improves. Moreover, timely interventions help preserve safety. Malfunctioning hydraulic systems can cause uncontrolled movements or equipment stalls, which may pose hazards to operators. By addressing issues as they arise, businesses save on costly emergency repairs, extend component life, and protect their investment in machinery.

Tailored Solutions and Quality Assurance for Reliability

Every machine has unique operating requirements, and hydraulic repair services must adapt accordingly. Customizing repairs—selecting the right replacement parts, calibrating components, and adjusting fluids—ensures systems operate optimally. Skilled technicians take into account environmental factors, usage intensity, and manufacturer guidelines to provide precise interventions.

Quality assurance is equally important. Thorough testing, including leak detection, pressure checks, and functional assessments, confirms that repairs meet high standards. Documentation of each repair and maintenance activity provides a historical record, allowing businesses to track performance trends, plan future servicing, and ensure compliance with safety standards.

By combining tailored solutions with strict quality control, hydraulic repair services help businesses maintain reliable, long-lasting equipment that supports productivity and safety. The peace of mind from knowing your machinery is fully serviced allows companies to focus on operations without constantly worrying about unexpected breakdowns.

Skilled hydraulic repair services are more than just fixes—they are an investment in equipment longevity, operational efficiency, and workplace safety. Through preventive maintenance, timely repairs, expert diagnostics, customization, and quality assurance, these services provide measurable benefits that save money and reduce downtime.

Whether it’s maintaining hydraulic cylinders, optimizing fluid performance, or addressing leaks and heat issues, professional repair services ensure that machinery remains dependable over the long term. For companies seeking to protect their assets and maximize operational efficiency, engaging expert technicians is essential. To ensure your hydraulic systems continue to perform at their best and protect your valuable machinery, contact Rivas Hydraulics LLC today for professional hydraulic repair services.