September 15, 2025

Understanding when to repair or replace hydraulic equipment can be crucial for maintaining operational efficiency and cost-effectiveness. With the complexity and variety of hydraulic systems in different industries, the decision-making process can be daunting. This article delves into essential factors that must be considered when faced with the decision between hydraulic repair and replacement. Both options have their respective advantages and challenges, which can significantly impact a company's operations. By comprehensively evaluating these factors, businesses can ensure that their hydraulic systems continue to meet operational demands effectively.

The decision to repair or replace hydraulic components often stems from the need to optimize costs while maintaining performance. Downtime caused by faulty equipment can be detrimental to operations, leading to financial losses and project delays. By being informed about the conditions and limitations of hydraulic systems, companies can proactively manage their maintenance strategies. Moreover, according to Verified Market reports, with the global hydraulic component repair market valued at USD 10 billion in 2023 and projected to grow at a 6% CAGR through 2030, understanding market trends is essential for planning investments. Therefore, a well-informed decision can save costs and boost the overall productivity of operations, especially when hydraulic repair options are thoroughly evaluated.

This article provides detailed insights into the criteria required for deciding between repair and replacement, including an exploration of cost factors, technological advancements, environmental impacts, and strategic considerations. The document will guide you through every facet of the decision-making process. From performance and lifespan evaluations to the implications of newer technology, each section equips you with necessary knowledge. Furthermore, case studies and industry insights offer practical perspectives that enrich your understanding. This structured approach aims to empower businesses in making decisions that align with operational goals and market realities through effective hydraulic repair planning.

Assessing the Condition of Hydraulic Components

Identifying Wear and Tear

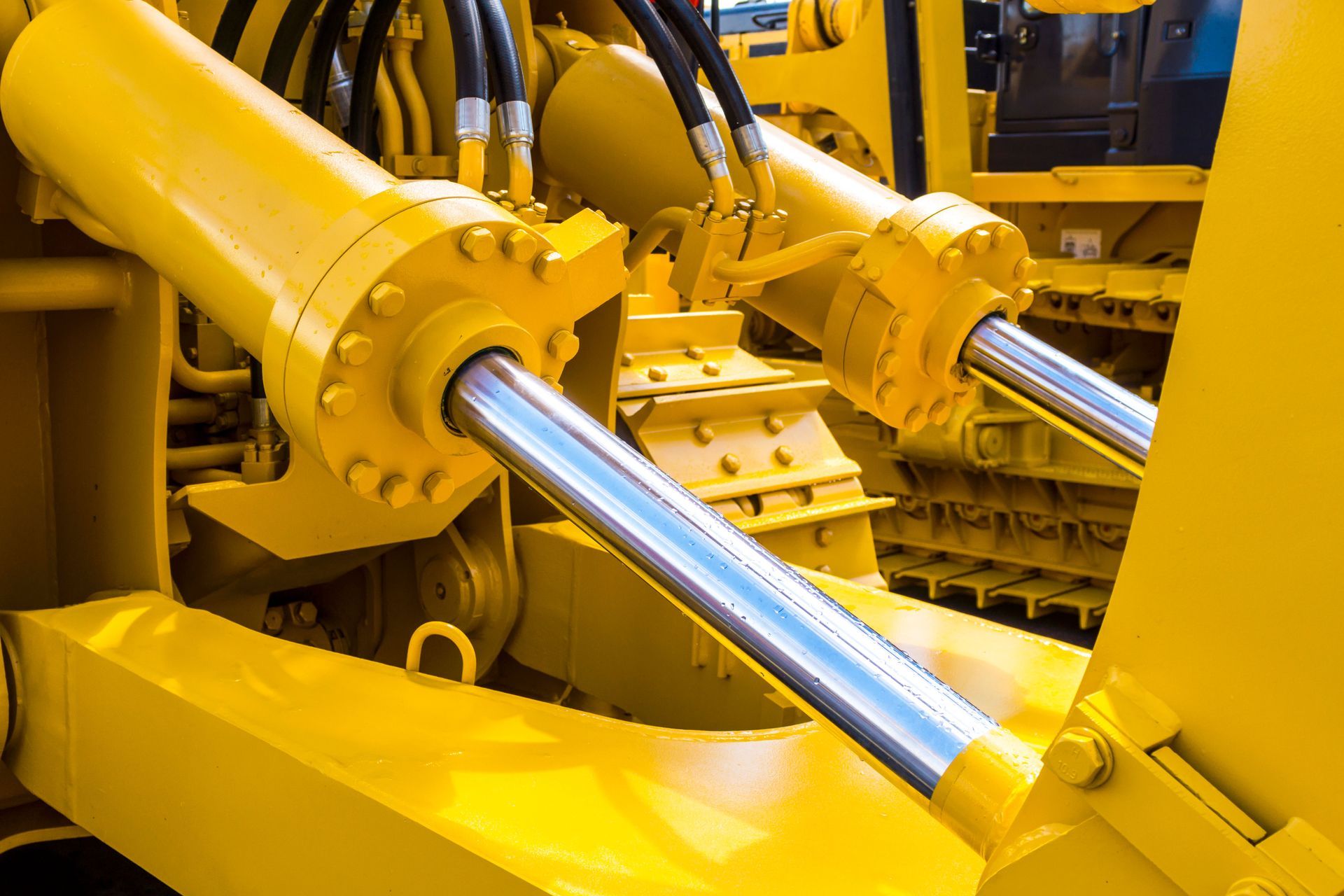

Identifying wear and tear is a critical first step in evaluating hydraulic components. Signs such as fluid leaks, unusual noises, and physical damage like cracks and corrosion indicate potential issues. Regular inspections can help in proactively identifying these signs before they escalate into costly failures. Wear and tear often depend on usage conditions, such as exposure to harsh environments or heavy loads. By systematically assessing these factors, a decision on whether hydraulic repair is feasible or replacement is more prudent can be made.

Performance testing helps ascertain the efficiency and functionality of hydraulic systems. Through such testing, it's possible to measure the component’s current capacity against its original specifications. A decline in performance can signal issues that may not be immediately visible during a physical inspection. Regular performance testing helps in identifying these hidden flaws and can inform the decision to repair or replace. In industries where precision and reliability are paramount, ensuring that a hydraulic system performs optimally is critical, making timely hydraulic repair efforts essential.

Evaluating the lifespan of hydraulic components can offer insights into their future reliability. Essential tools for this analysis include operating hours, system cycles, and historical performance data. Such evaluations help anticipate future failures and plan accordingly. This approach not only aids in cost management but also minimizes operational disruptions. Organizations can strategically plan maintenance work and budget allocations based on expected lifespans, including decisions about hydraulic repair timing and scope.

Cost Considerations: Repair vs. Replacement

Initial vs. Long-Term Costs

Cost considerations play a pivotal role in the decision to repair or replace hydraulic components. Immediate repair costs may appear lower than purchasing new equipment, but long-term benefits of newer technology could outweigh initial expenses. New components might offer better efficiency or come with extensive warranties that lower future maintenance expenses. Consequently, companies must weigh the pros and cons of both options to make a balanced decision. An overall view considering both short-term and extended implications on costs can provide clarity.

Budget constraints significantly influence whether a company opts for repair or replacement. Limited financial resources may necessitate opting for repairs as a temporary solution. However, these decisions made due to budget constraints must also consider the likelihood of recurring issues and associated cumulative costs. The allocation of sufficient budget for capital investments may better facilitate new equipment acquisition. Therefore, a thorough financial analysis is crucial to ensure sustainable and efficient asset management with proper hydraulic repair strategies.

Potential downtime costs also sway repair versus replacement decisions. Prolonged equipment downtime can result in hefty financial losses and strain operational schedules. While some repairs can be completed swiftly, more complex ones might require extensive downtime, justifying replacements. In contrast, immediate replacement might prevent any temporary operational halt. Hence, the cost of downtime should be factored into overall cost considerations to choose the most viable option.

Technology Upgrades and Compatibility

Advancements in Hydraulic Technology

The technological landscape for hydraulic systems has evolved with innovations improving both efficiency and operational reliability. Businesses benefit from newer models that often include improvements in energy conservation, precision, and control. Evaluating whether these advancements align with operational needs warrants a foresight approach in technological upgrades. Opting for repair might forego these benefits, whereas replacement allows leveraging modern technology for improved productivity. Thus, staying informed about technology trends is vital for informed decision-making regarding hydraulic systems.

Compatibility with existing systems is a critical factor when considering repairs, replacement, or upgrades. Newer technology might offer performance benefits, but integration with current systems could pose challenges. Incompatibility issues can lead to substantial expenses or more significant system overhauls. This requires thorough technical assessments to ensure that added components or systems successfully integrate with existing infrastructure. Proper evaluation ensures seamless incorporation without jeopardizing current operations.

Integration challenges are not just technical but also include operational and human aspects. When new technology is implemented, staff training becomes necessary to maximize its potential. Repairs often involve addressing familiar systems that pose fewer learning curves for existing staff. However, replacement with cutting-edge technology necessitates resources for training, documentation transitions, and potential adjustments in operational routines. Overcoming these integration challenges through strategic planning is essential for realizing the full benefits of new technology adoption.

Evaluating Environmental Impact

Sustainability Considerations

In today's responsible business climate, sustainability considerations cannot be overlooked in operational decisions. Repairing existing components can be aligned with sustainable practices by maximizing resource usage and minimizing waste. Nonetheless, new technology may offer greener alternatives that have lesser environmental footprints in the long term. Balancing the immediate environmental impact with future benefits should drive repair-versus-replacement decisions. Companies must analyze the total resource consumption of both paths for a complete sustainability perspective.

The disposal of old equipment raises profound environmental concerns that need addressing. Organizations must ensure obsolete components are appropriately recycled or safely disposed of, aligning with environmental regulations and sustainability goals. Choosing replacements not only provides improved efficiency but might also help circumvent complex disposal requirements of inoperative equipment. However, the dismantling and recycling processes require trained personnel and dedicated disposal plans. By considering these factors, businesses can further their commitment to environmental stewardship.

Energy efficiency is an area where new technology often outperforms older systems. Investigating the energy efficiency of equipment, both existing and potential replacements, garners insights on operational costs and carbon footprint reductions. Newer systems often utilize advanced technologies that consume less energy, potentially resulting in cost savings and reduced environmental impact. The payoff may be equally or more significant with energy-efficient replacements. Understanding these efficiency facets is crucial for an environmental and budget-friendly decision.

Decisions regarding hydraulic repair or replacement require careful consideration of multiple factors like condition, cost, technology, and environment. Reviewing the condition through expert evaluations, estimating costs, and contemplating environmental impacts ensures a holistic decision-making approach. Embracing new technology can lead to sustainable operational advantages and future-proofing processes. Therefore, informed choices facilitate improved productivity, budgetary control, and sustainable practices. Businesses can enhance efficiency and effectiveness by diligently evaluating these aspects, ensuring optimized outcomes in their hydraulic equipment management. If your machinery needs hydraulic repair, make sure to contact Rivas Hydraulics LLC today!